| Worm/Screen Centrifuge | |||||||||||||||||||||||||||||||||||||||||||||||||

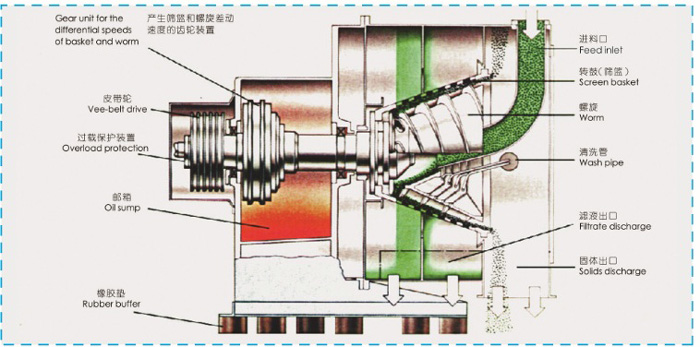

◆ The main purpose: For adipic acid, salt, AH- salt, ammonium sulfate, gypsum, ammonium nitrate, ammonium phosphate, ammonium sulfate, ammonium carbonate, ammonium sulfate, sulfide ion exchange resin, sodium chloride, sodium chlorate, anthracene, aspirin, calcium formate, manganese sulfate, borax, methyl cellulose, sodium borohydride, sodium formate, sodium nitrate, too sodium borate, sodium phosphate, citric acid, sodium sulfate, sodium borate, polystyrene, polystyrene four alcohol, soda, copper sulfate, potash (potassium carbonate), tartaric acid, crystallization of soda, potassium alum, sodium phosphate three, potassium bicarbonate, zinc sulfate, pentaerythritol four alcohol, acetic acid, and plastic particles potassium chloride, five potassium sulphide, two potassium phosphate, potassium sulfate. ◆ The main features: The 1 main parts, drum and spiral corrosion resistance of stainless steel and titanium alloy made available. 2, special filter mesh, filter thickness up to 2.5mm, the service life is longer. 3, drum speed stepless speed regulation. 4, screw differential speed adjustable, there is a class or stepless speed regulation. 5, simple and reliable way of lubrication. 6, safety protection: speed detection, over vibration protection, motor overload protection, spiral zero differential protection. 7, for large viscosity material, can choose the hydraulic differential, the work is stable and reliable. Get to the speed difference between drum and spray from suspension feeding tube into spiral cavity, and through the screw head near the cone end at the bottom of the material outlet into the drum in centrifugal force field under the action of slurry in the liquid phase by setting the wall screen is separated out, solid particles are trapped in the drum; at the same time, the drum of solid particles in centrifugal force and spiral effect of the drum from the small end of drum movement and in the movement process, due to the fact that the rotating diameter increases, centrifugal force increasing rapidly, solid phase from the initial entry of high moisture content in solid phase to discharge drum to low moisture solid content, so as to realize the solid-liquid phase automatic and continuous separation. ◆ The technical parameters:

|

|||||||||||||||||||||||||||||||||||||||||||||||||